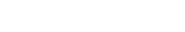

PLATE HEAT EXCHANGERS

Our Key Areas of Expertise Include:

PLATE HEAT

EXCHANGERS

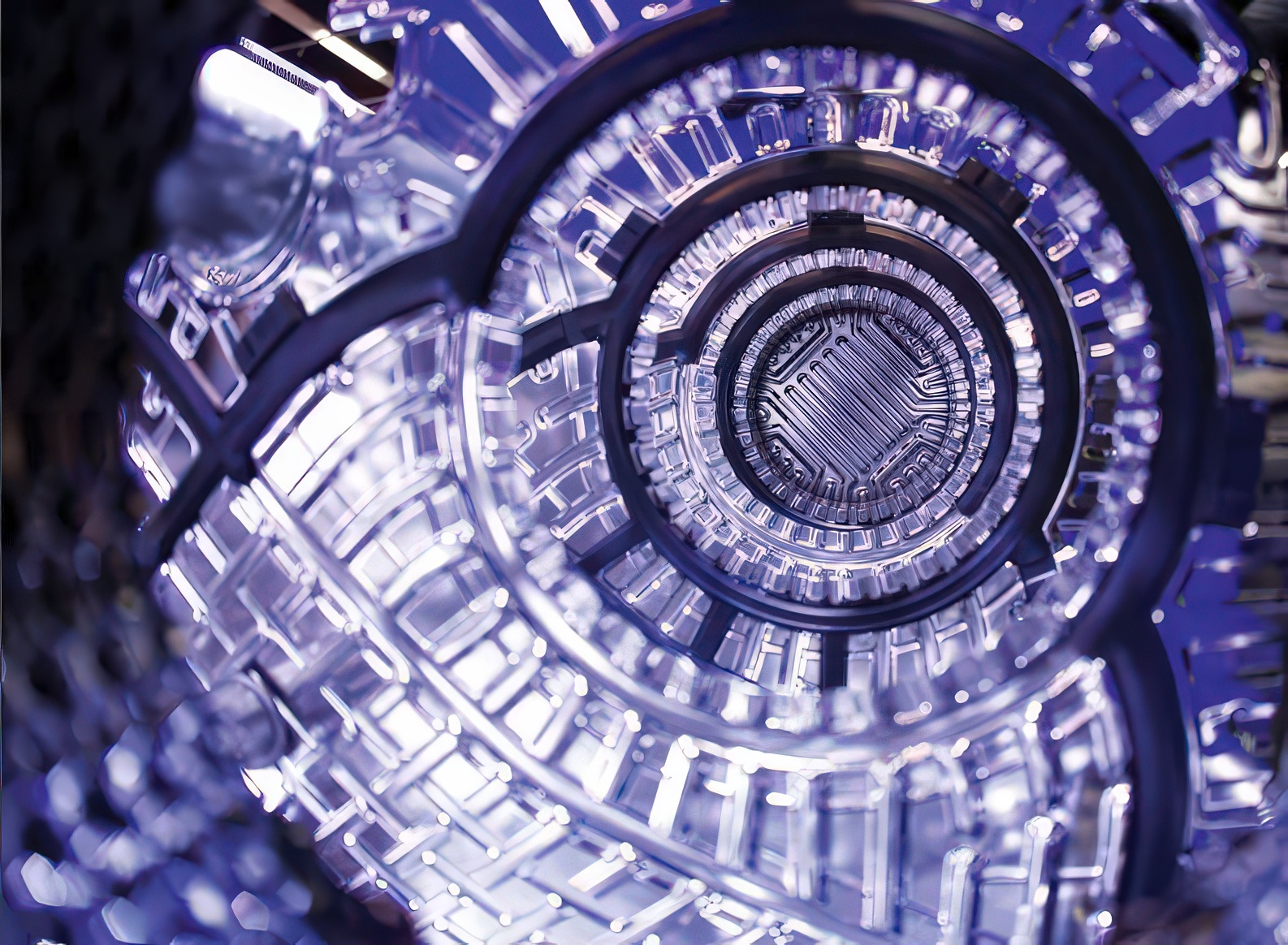

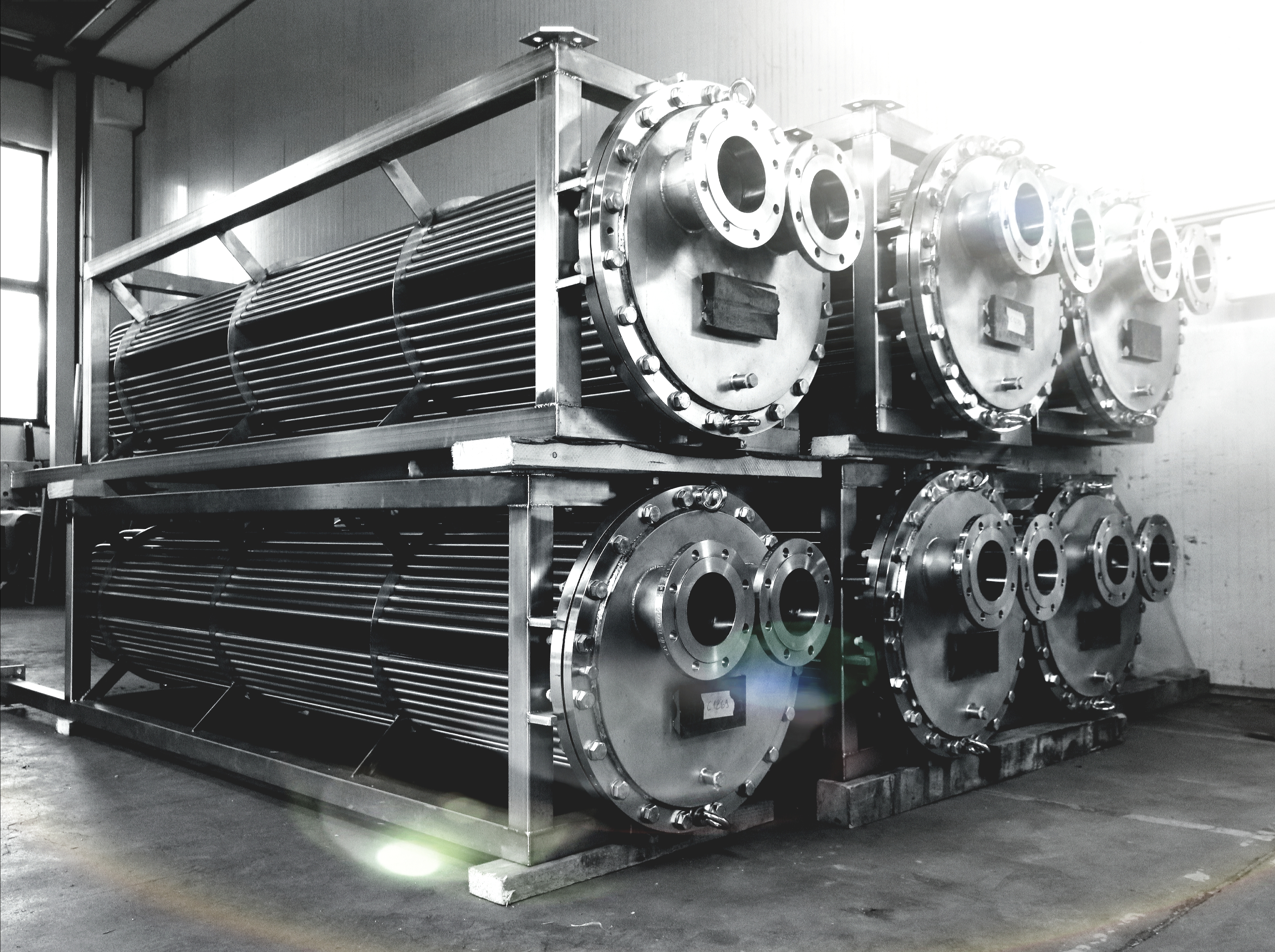

SHELL AND TUBE

HEAT EXCHANGERS

HEAT EXCHANGER

SERVICE

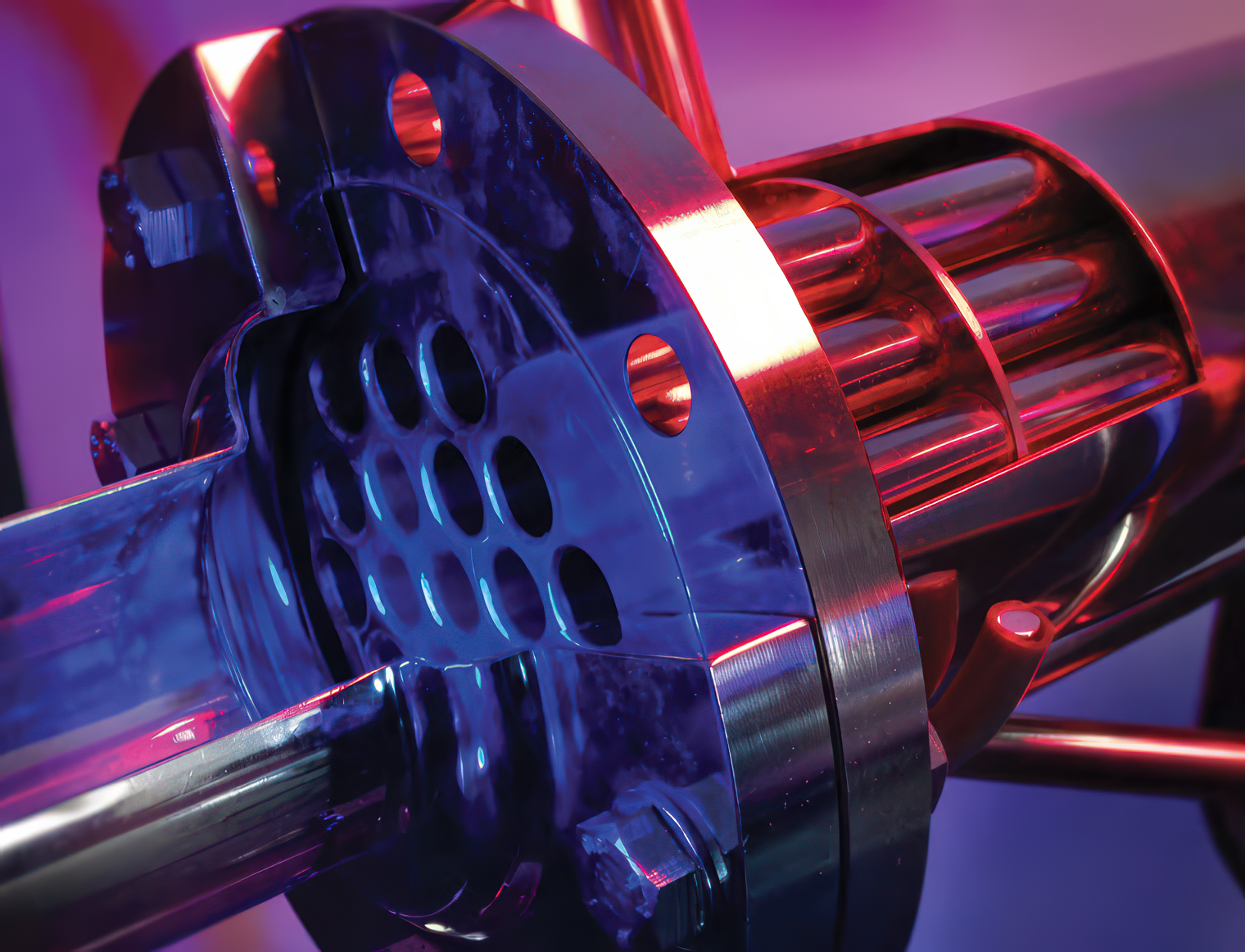

AIR COOLERS

AND HEATERS

About us:

Ipros Hex has over 35 years of experience in the field of heat transfer. We pride ourselves on state-of-the-art technology, expert staff, and top-notch expertise, enabling our engineers to find the right solution for even the most complex challenges.

Our Offer:

We are known for reliability across various fields, including HVAC, green technology, chemical, petrochemical, sugar, food, and pharmaceutical industries. Our product range includes brazed, gasketed, and welded plate heat exchangers, as well as tubular heat exchangers. Additionally, we offer air or gas coolers and heaters. Our experts will help you find the right and efficient solution tailored precisely to your requirements.

Service:

Ipros Hex is qualified to service, install, commission, and maintain all types of heat exchangers. Our service is based on many years of experience in manufacturing and maintaining heat exchangers. We also provide spare parts, periodic inspections, and maintenance programs to help you enhance the efficiency of your production.

Contact Us

Send us a message using the form below.